ESI’s new thermal vacuum chamber is up and running

This past week, members of the Earth & Space Institute finished commissioning their new thermal vacuum chamber (TVAC), a breathtaking piece of engineering—literally! In the aerospace industry, TVACs are used to simulate the space environment by evacuating the air in the chamber and cooling test articles to their on-orbit temperatures. In space, satellites operate in a vacuum, meaning they must manage heat in the absence of air. Thermal vacuum tests give engineers pre-launch insight into how their satellite’s thermal system will perform in orbit, whether it will survive the thermal environment, and how well thermal models predict the actual performance.

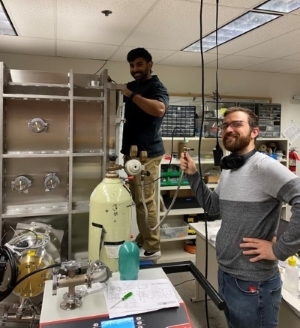

Photo: ESI presents its new thermal vacuum chamber (TVAC). Photo courtesy of D. Nelson.

Typically, TVAC testing needs to be outsourced to external labs, but ESI’s new chamber will allow these tests to happen right here at UMBC. For a group that designs and builds its own hardware in house, this is an important capability. Work began on this chamber over a year ago, after ESI was awarded a Maryland congressional grant. Designing, building, and testing this equipment was one of the main efforts the grant enabled—and it was no small effort. Everything from the chamber’s internal volume to its power requirements to the feasibility of moving it from the loading dock to the third floor of the Physics building was a consideration for the engineers.

Photo: In UMBC's Physics building, there was just enough clearance to get the chamber through the 3rd floor corridor to the lab. Photo courtesy of D. Nelson.

Photo: ESI interns Jacob Thomas (UMBC ME graduate student) and Lars Sobieski (UMBC ME undergraduate student) perform a leak check on the sealed chamber. Photo courtesy of D. Nelson.

Photo: ESI interns Jacob Thomas (UMBC ME graduate student) and Lars Sobieski (UMBC ME undergraduate student) perform a leak check on the sealed chamber. Photo courtesy of D. Nelson.

Since the chamber arrived in January 2025, ESI engineers and engineering interns have been hard at work building its plumbing and control system. Now, the TVAC is fully functional, able to reach pressures as low as 5*10-7 mBar—over 2 billion times lower than atmospheric pressure! Soon ESI will begin using this new facility to test electronics and optical sensors they plan to use in future space missions.

While it’s been a long journey already, this is only the beginning for ESI’s improved in-house space simulation and ground testing capabilities.

Photo, l - r: ESI interns Jacob Thomas and Lars Sobieski along with ESI engineers Danny Nelson, CJ Escobar, and Dominik Cieslak all played roles designing, building, and commissioning the chamber. Photo provided by D. Nelson.

(Thanks to Danny Nelson for providing this article!)

Posted: August 8, 2025, 5:30 PM